Material Description & Properties

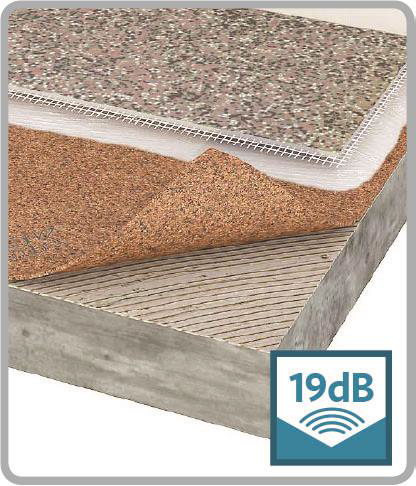

ΔLw = 16dB–19dB

ΔLw = 16dB–19dB

Agglomerated cork and recycled rubber, underlay for impact noise reduction and thermal insulation. Suitable for floating, hardwood, vinyl, linoleum and ceramic floors.

| Flooring | Thickness (mm) | ΔLw (dB)(1) | IIC (dB)(2) |

| Non-Glued Laminate 3 19 47 | 3 | 19 | 47 |

| Glued-Down Wood 3 16 50 | 3 | 16 | 50 |

| Ceramic (or Natural Stone)

|

3 | 16 | 51 |

| 4.5 | 18 | 52 | |

| LVT | 3 | 19 | 51 |

(1) ISO 10140-3 & ISO 717-2

(2) ASTM E492-09 & ASTM E989-06

| Thickness (mm) | Width (m) x Length (m) |

|

3 |

1 x 15 |

|

4.5 |

1 x 15 |

| Specific Weight(1) | Tensile Strength(1) | Compression at 0,7MPa(1) | Recovery after 0,7MPa(1) | Durability |

| 650-700Kg/m3 | >800KPa* | <15% | >75% | Lifetime of building |

The following installation instructions are recommended by Amorim Cork Composites but are not intended as a definitive project specification. They are presented in an attempt to be used with recommended installation procedures of the flooring manufacturers.

Room Conditions: Temperature > 10ºC / Room moisture content < 75%.

Subfloor: All subfloor work should be structurally sound, clear and level. The moisture content of the subfloor should not be more that 2.5% (CM) by weight measured on concrete subfloors.

Isolation vapour barrier

A p.e. insulation vapour barrier covering the entire flooring area, minimum 50mm wide vertically around the perimeter of the entire floor MUST be installed prior to the Acoustic Cork Underlay. Install by overlapping (minimum 100mm) the p.e. foil, and use an adequate tape to adhere/fix it, if necessary. After completion, p.e. foil should cover the entire concrete area without gaps. Never mechanically fasten the p.e. foil barrier with screws, nails or staples as this will severely diminish the performance of the insulation barrier.

Installations Instructions

Unpack the Acoustic Cork Underlay at least 24h before the installation and store it in the room where the installation will take place. Cut the Acoustic Cork Underlay to desired length and install directly over the entire floor pulled 30mm up the walls with crown of the rolled materials up (label side down), removing all trapped air. After completion, the Acoustic Cork Underlay should cover the entire flooring area without gaps and with joints butted tight and preferably taped.

Final Flooring

Always follow manufacturers recommended installation instructions.

Perimeter Insulation Barrier

Install a perimeter insulation barrier minimum 35mm wide vertically around the entire perimeter of the room. This is highly recommended in order to avoid lateral propagation of impact noise. Spot adhere the strips to the wall using acrylic glue or a bead of silicone sealant (do not forget the edges of pipes, ducts, etc). Before the installation of the skirting boards, the insulation strips must be levelled (trimmed) to the height of the wood.

Installations Instructions

Unpack the Acoustic Cork Underlay at least 24h before the installation and store it in the room where the installation will take place. Use a properly sized V-notched trowel and acrylic glue to glue the Acoustic Cork Underlay to the concrete slab. Always follow the glue manufacturers recommended instructions. Cut the Acoustic Cork Underlay to the desired length and install directly over the subfloor with crown of the rolled materials up, removing all trapped air. Butt the Acoustic Cork Underlay directly against the insulation perimeter barrier already installed. Put the loose laid material back. Using a properly sized V-notched trowel, apply acrylic glue to the concrete slab. Gently, return the pulled back material to its measure place and roll in both directions with a roller. Proceed to cover the entire floor making sure that the joints are butted tight. After completion, the Acoustic Cork Underlay should cover the entire flooring area without gaps and with joints securely taped.

Final Flooring

Use polyurethane based adhesive. Always follow manufacturers recommended installation instructions.

Perimeter Insulation Barrier

Install a perimeter insulation barrier minimum 35mm wide vertically around the entire perimeter of the room. This is highly recommended in order to avoid lateral propagation of impact noise. Spot adhere the strips to the wall using acrylic glue or a bead of silicone sealant (do not forget the edges of pipes, ducts, etc). Before the installation of the skirting boards, the insulation strips must be levelled (trimmed) to the height of the tiles.

Installations Instructions

Unpack the Acoustic Cork Underlay at least 24h before the installation and store it in the room where the installation will take place. Use a properly sized V-notched trowel and acrylic glue to glue the Acoustic Cork Underlay to the concrete slab. Always follow the glue manufacturers recommended instructions. Cut the Acoustic Cork Underlay to the desired length and install directly over the subfloor with crown of the rolled materials up, removing all trapped air. Butt the Acoustic Cork Underlay directly against the insulation perimeter barrier already installed. Put the loose laid material back. Using a properly sized

V-notched trowel, apply acrylic glue to the concrete slab. Gently, return the pulled back material to its measure place and roll in both directions with a roller. Proceed to cover the entire floor making sure that the joints are butted tight. After completion, the Acoustic Cork Underlay should cover the entire flooring area without gaps and with joints securely taped.

Final Flooring

Use a flexible cement glue. Always follow manufacturers recommended installation instructions.

Perimeter Insulation Barrier

Install a perimeter insulation barrier minimum 35mm wide vertically around the entire perimeter of the room. This is highly recommended in order to avoid lateral propagation of impact noise. Spot adhere the strips to the wall using acrylic glue or a bead of silicone sealant (do not forget the edges of pipes, ducts, etc). Before the eventual installation of the skirting boards, the insulation strips must be levelled (trimmed) to the height of the final floor.

Installations Instructions

Unpack the Acoustic Cork Underlay at least 24h before the installation and store it in the room where the installation will take place. Use a properly sized V-notched trowel and acrylic glue to glue the Acoustic Cork Underlay to the concrete slab. Always follow the glue manufacturers recommended instructions. Cut the Acoustic Cork Underlay to the desired length and install directly over the subfloor with crown of the rolled materials up, removing all trapped air. Butt the Acoustic Cork Underlay directly against the insulation perimeter barrier already installed. Put the loose laid material back. Using a properly sized V-notched trowel, apply acrylic glue to the concrete slab. Gently, return the pulled back material to its measure place and roll in both directions with a roller. Proceed to cover the entire floor making sure that the joints are butted tight. After completion, the Acoustic Cork Underlay should cover the entire flooring area without gaps and with joints securely taped.

Final Flooring

Use polyurethane based adhesive. Always follow manufacturers recommended installation instructions.

We are here to discuss your application and assist you in selecting the right thermal break materials to meet your project specification.

Disclaimer. These figures are typical values for the material and do not represent a product specification. Properties will vary depending on source of raw material, method of processing, physical from of product, direction of measurement etc.

Updated 04/03/2020